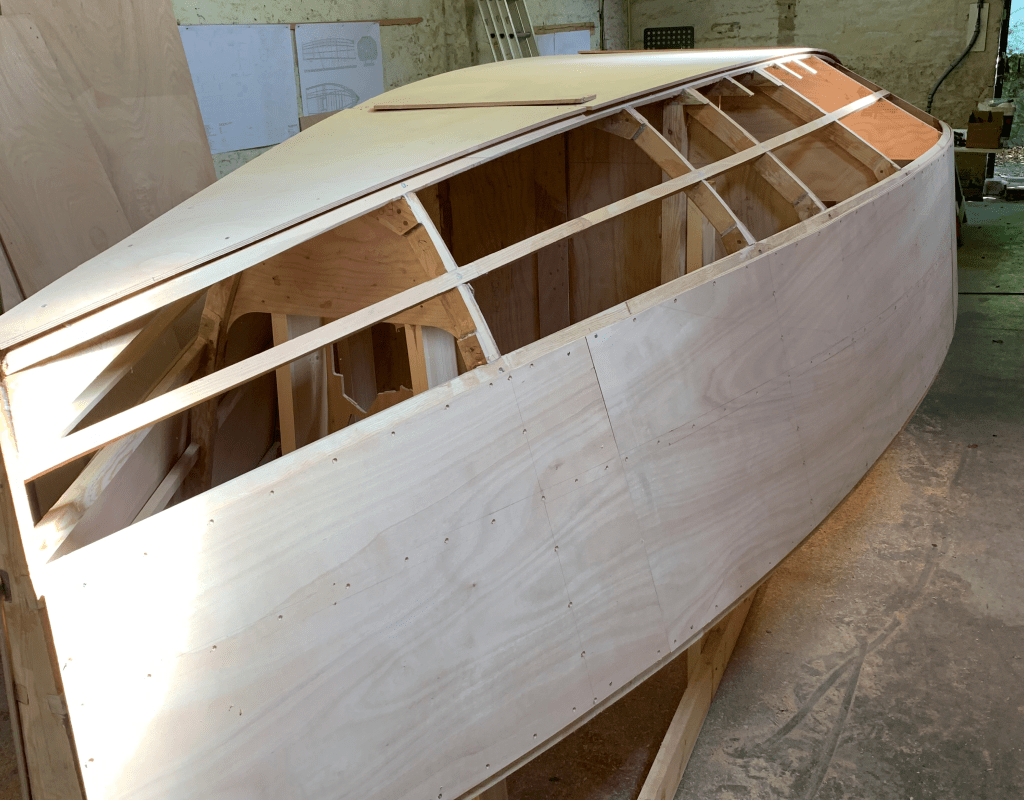

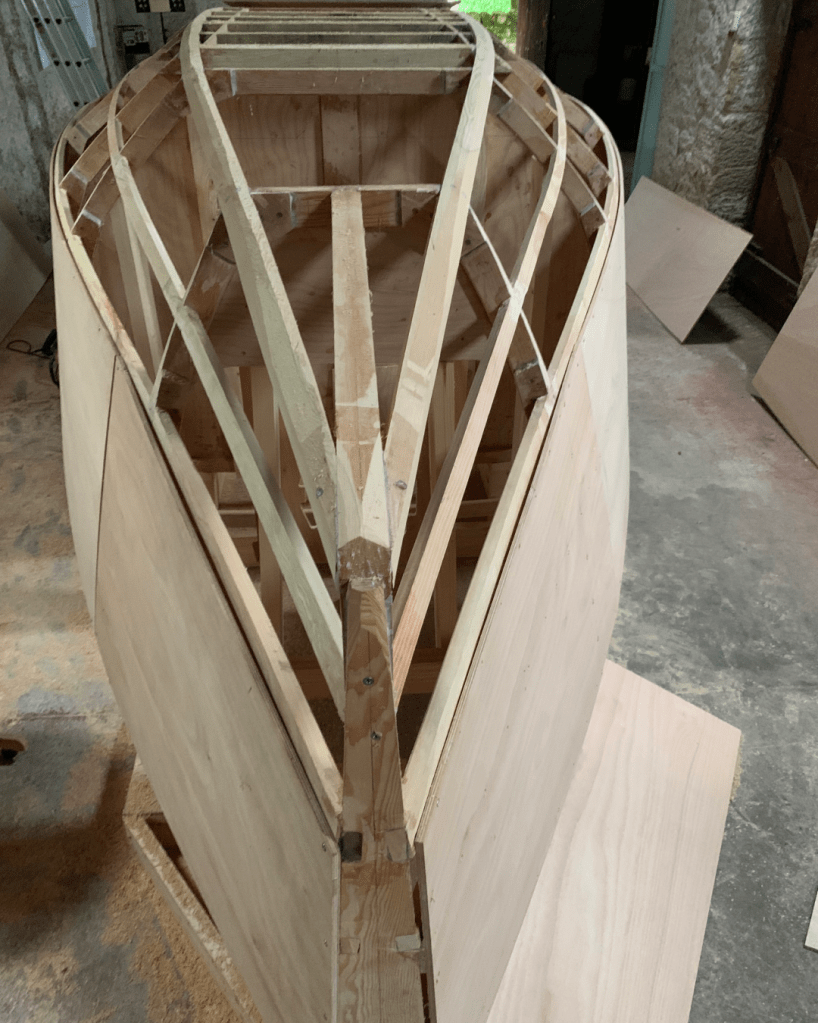

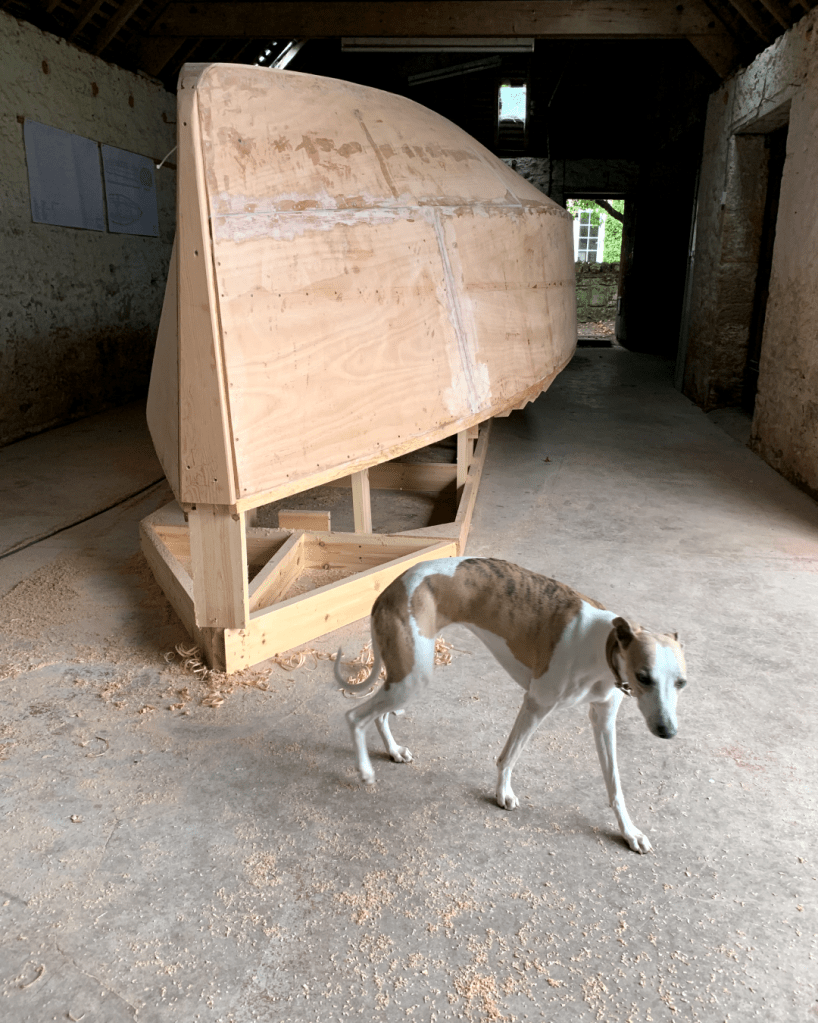

After further tweaks and dry fits I screwed and glued the strings in place. I gave all the hull boards a coat of epoxy on their inner side before I started and all the stringers the same. I started with the topsides, then the hull bottom and finally filled in the middle section. I decided to use slightly thickened epoxy to bond the bottom hull boards together. The middle chines are a not easy!

I don’t think my technique was the best but it eventually worked. I used clamps and straps to help and didn’t find any benefit from gradually bending the ply into shape. The process took much longer than I’d thought. Working alone again means things take more than twice as long. I spent two to three weeks on this phase.

Leave a comment